Foxconn’s AI Push: Revolutionizing Manufacturing with Large Language Models

Introduction to Foxconn and Smart Manufacturing

Foxconn, also known as Hon Hai Precision Industry Co., Ltd., is a prominent global leader in manufacturing, renowned primarily for its production of electronic devices. Founded in 1974 by Terry Gou, Foxconn has established itself as a cornerstone of the electronics supply chain, producing devices for major companies, including Apple, Microsoft, and Sony. With a workforce exceeding a million employees and facilities across multiple countries, Foxconn plays a critical role in shaping the future of manufacturing and technological innovation.

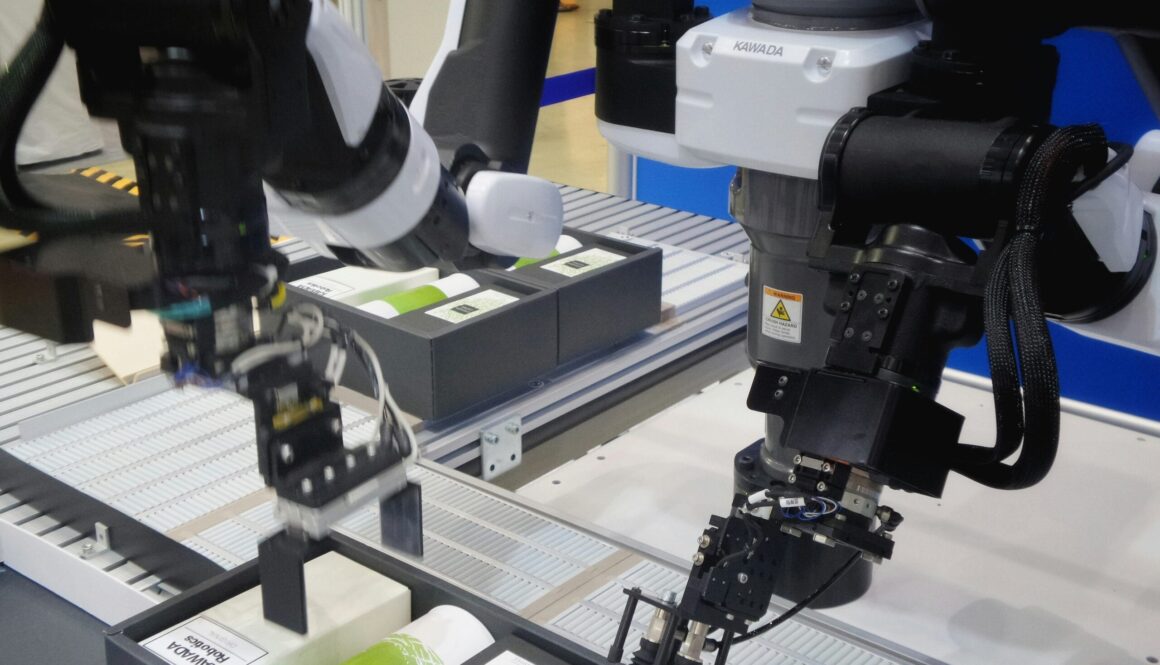

The emergence of smart manufacturing represents a transformative shift in traditional production methods. This concept incorporates advanced technologies into manufacturing processes, facilitating increased efficiency, improved quality, and enhanced flexibility. Smart manufacturing harnesses innovations, such as the Internet of Things (IoT), robotics, and artificial intelligence (AI), thereby revolutionizing the way goods are produced. By integrating these technologies, manufacturers can achieve real-time monitoring and data analysis, allowing for proactive decision-making and optimized operations.

The integration of AI into manufacturing processes is particularly significant for companies like Foxconn. AI-driven tools and large language models enable more efficient communication, sophisticated data interpretation, and streamlined operations. These AI technologies can analyze vast amounts of data, generating insights that enhance production planning, predict equipment failures, and improve overall quality control. Moreover, the ability of these models to automate routine tasks frees human workers to focus on more complex functions, thereby enriching the workforce experience.

The potential benefits of integrating AI into smart manufacturing are immense, ranging from cost reduction to accelerated production timelines. As Foxconn embraces these advancements, it positions itself at the forefront of the manufacturing revolution, demonstrating the vast possibilities that lie in the marriage of AI and production technologies.

The Launch of Foxconn’s Large Language Model (LLM)

Foxconn has recently announced the launch of its first large language model (LLM), a significant milestone in the company’s ongoing integration of artificial intelligence within its manufacturing processes. This LLM is poised to transform various aspects of production, ranging from automation of communication to enhancing decision-making capabilities. Designed to foster efficiency, the LLM will be utilized in applications such as predictive maintenance, supply chain optimization, and real-time problem-solving.

The large language model operates on a sophisticated architecture that utilizes deep learning techniques, enabling it to analyze vast amounts of data and generate human-like text. This capability allows for seamless interactions between machines and human operators, ultimately leading to improved productivity and operational insights. By leveraging natural language processing, Foxconn’s LLM can process technical documentation, generate reports, and even assist in training personnel, thereby reducing the time required for onboarding and skill acquisition.

Furthermore, this launch aligns with Foxconn’s broader AI strategy, which aims to strengthen its competitive edge in the manufacturing sector. By embedding advanced AI technologies into its operations, the company seeks to enhance precision and reduce downtime, factors critical to maintaining a robust production pipeline. The implementation of the LLM is expected to streamline workflows and facilitate data-driven decision-making, enabling Foxconn to respond more effectively to the evolving demands of the global supply chain.

In essence, the introduction of Foxconn’s large language model signifies a pivotal move towards a more intelligent manufacturing landscape. As companies increasingly adopt AI solutions, the potential for increased efficiency and innovation in production processes becomes markedly promising. This launch not only underscores Foxconn’s commitment to technological advancement but also sets the stage for further developments in AI-driven manufacturing in the future.

AI in Supply Chain Management

The integration of artificial intelligence (AI) in supply chain management is rapidly transforming traditional methodologies into more efficient and responsive frameworks. With the advent of large language models (LLMs), companies are now equipped with powerful tools that enhance their forecasting, demand planning, logistics, and risk management processes. These advancements pave the way for a more streamlined supply chain by enabling data-driven decision-making.

One of the significant areas where LLMs can make an impact is in forecasting. By analyzing vast datasets and recognizing patterns that human analysts might overlook, AI systems can predict demand fluctuations with greater accuracy. This translates to optimized inventory levels, reduced stockouts, and minimized excess inventory, ultimately resulting in cost savings and improved customer satisfaction. Additionally, the capability of LLMs to simulate various market scenarios allows organizations to prepare for potential market disruptions.

In terms of demand planning, LLMs enhance the traditional planning process by incorporating real-time data, which reflects current market conditions more accurately than historical data alone. This adaptability fosters agility within the supply chain, enabling businesses to respond swiftly to changing consumer preferences or external factors such as economic shifts or weather events.

Logistics is another critical area benefiting from AI integration. The sophisticated algorithms employed by LLMs can optimize routing, reduce delivery times, and improve overall transportation efficiency. By leveraging these tools, companies can lower operational costs while ensuring that products reach their destinations in a timely manner, enhancing overall service levels.

Lastly, risk management stands to benefit significantly from AI advancements. LLMs can analyze risk factors related to suppliers, geopolitical issues, and natural disasters, enabling companies to develop proactive strategies. By identifying potential threats early and formulating mitigation strategies, organizations can safeguard their supply chains against unforeseen disruptions.

Impact on Workforce and Employment

The integration of Artificial Intelligence (AI) technologies, particularly Large Language Models (LLMs), into manufacturing processes is poised to significantly alter the workforce landscape at Foxconn and throughout the industry. As these technologies automate various tasks, concerns arise about potential job displacement. However, it is essential to consider not only the risks but also the opportunities that may emerge from these advancements.

Historically, the manufacturing sector has been characterized by its adaptability in the face of technological evolution. Previous shifts, such as the introduction of robotics and automation in assembly lines, initially raised fears of widespread unemployment. Instead, these changes have often led to the creation of new roles that require advanced technical skills. In a similar vein, the deployment of LLMs may streamline certain repetitive tasks, thereby enabling employees to transition toward more complex and higher-skilled positions. As AI handles data processing and communication tasks, workers may focus on areas that require critical thinking, problem-solving, and innovation.

Moreover, the rise of AI technologies presents an opportunity for workforce reskilling and upskilling initiatives. Organizations like Foxconn can invest in training programs aimed at equipping employees with the necessary competencies to adapt to new roles in the tech-driven manufacturing landscape. This proactive approach not only mitigates the negative impact of job displacement but also enhances employee engagement and job satisfaction, as workers find themselves in more dynamic and fulfilling positions.

While the potential for job displacement exists, an optimistic perspective reveals that the implementation of LLMs may ultimately lead to a modernization of the workforce, fostering the emergence of technology-centric roles. By embracing this evolution, Foxconn can ensure that its employees are prepared for the challenges and opportunities that lie ahead, fostering a resilient and adaptable work environment in the face of AI’s rapid integration into manufacturing.

Comparative Analysis: Foxconn vs. Competitors

In the rapidly evolving manufacturing landscape, the integration of artificial intelligence (AI) is becoming increasingly pivotal. Foxconn, a leading global electronics manufacturer, is making significant strides in utilizing large language models (LLMs) to enhance its manufacturing processes. This increase in AI capabilities places Foxconn in a competitive position, yet it faces formidable rivals also leveraging similar technologies. To understand Foxconn’s unique approach, it is essential to compare its initiatives with those of its primary competitors.

Companies such as Siemens and General Electric (GE) have long been at the forefront of AI implementation in manufacturing. Siemens’ Digital Industries division has introduced the Siemens Xcelerator, which utilizes AI to optimize product lifecycle management and predictive maintenance. Similarly, GE has invested in its Predix platform, aimed at monitoring equipment performance in real-time, thus enhancing operational efficiency. These companies focus on integrating AI systems that promote data analytics, creating actionable insights for their manufacturing operations.

However, Foxconn’s approach is distinctive, primarily through its emphasis on large language models to streamline communication and decision-making processes on the factory floor. While Siemens and GE prioritize hardware and software integration, Foxconn leverages AI-driven chatbots and virtual assistants that facilitate seamless interaction among workers and management. This not only boosts productivity but also empowers employees with real-time access to operational data and resources.

Moreover, Foxconn is actively exploring partnerships with AI-focused startups, which allows for innovative solutions tailored to specific challenges within manufacturing. This collaborative strategy sets it apart from competitors that may rely more heavily on in-house development. The combination of advanced AI techniques with a focus on human-centric solutions positions Foxconn as a leader in manufacturing innovation, capable of adapting and evolving with the industry’s changing demands.

Challenges in AI Implementation

The integration of large language models (LLMs) within Foxconn’s manufacturing operations is poised to bring numerous advantages. However, this transformation also presents distinct challenges that require strategic management. One primary issue lies in the technical difficulties associated with implementing AI systems. Developing and deploying LLMs necessitates substantial investments in computing resources, sophisticated infrastructure, and accompanying software. These technical requirements can create significant obstacles, particularly for an organization as expansive as Foxconn, which operates in various locations worldwide.

Another considerable hurdle pertains to data privacy concerns. As Foxconn collects and analyzes vast amounts of data to inform LLM functionalities, ensuring compliance with data privacy regulations becomes paramount. This challenge is exacerbated by the differing legal frameworks regarding data handling across various jurisdictions. Protecting sensitive information while harnessing the potential of AI is critical, demanding careful planning and robust mechanisms to safeguard data integrity. Non-compliance can lead to severe implications, potentially tarnishing Foxconn’s reputation and incurring legal consequences.

Furthermore, workforce training and adaptation represent significant challenges in the AI implementation process. As Foxconn incorporates LLM technology, it is essential that employees, both at the management and operational levels, possess the necessary skills to collaborate with AI systems. This transition may require a cultural shift within the organization, as personnel adjust to new workflows and technology-enhanced processes. Designing comprehensive training programs that encompass technical expertise and facilitate ease of use will be crucial to integrating AI effectively. This commitment to upskilling ensures employees remain relevant and capable in an increasingly automated manufacturing landscape.

Future of AI in Manufacturing

The integration of artificial intelligence (AI) in manufacturing is anticipated to undergo transformative changes, spurred significantly by initiatives such as Foxconn’s push for large language models. As companies increasingly embrace AI technologies, several ongoing trends are expected to shape the future of the industry. One of the most promising developments is the enhancement of predictive analytics, which enables manufacturers to anticipate equipment failures, optimize supply chains, and streamline production processes. This capability relies on large datasets and sophisticated algorithms to forecast demand and mitigate risks, thereby improving operational efficiency.

Moreover, the advent of smarter automation solutions is likely to redefine the workforce landscape. AI-driven robotics and intelligent machines are set to assist human workers rather than replace them, augmenting productivity and ensuring safety in manufacturing environments. With advancements in natural language processing and machine learning, machines can better understand and respond to complex human commands, making human-robot collaboration more seamless. This collaboration could lead to increased agility and adaptability on the production floor, allowing manufacturers to respond swiftly to changing market demands.

Another anticipated trajectory is the personalization of manufacturing processes. Utilizing AI, manufacturers can rapidly prototype and produce customized products to meet individual consumer needs. This shift towards mass customization is indicative of a deeper consumer engagement in product development and presents opportunities for companies to differentiate themselves in a competitive market. Furthermore, with sustainability becoming a focal point, AI technologies may also drive greener manufacturing practices by optimizing resource usage and minimizing waste.

In conclusion, the future of AI in manufacturing appears promising, characterized by enhanced operational efficiencies, improved human-robot collaborations, and a strong push towards customization and sustainability. These advancements, coupled with ongoing innovations in large language models, signify a profound shift in how manufacturing processes will be conducted, ultimately reshaping the industry as it stands today.

Case Studies of Successful AI Integration

The integration of artificial intelligence (AI) into manufacturing has proven beneficial for several companies across various sectors. Notably, General Electric (GE) has implemented AI technology to enhance its manufacturing processes significantly. GE’s Digital Wind Farm, for instance, utilizes machine learning algorithms to analyze data from wind turbine performance in real-time. This system facilitates predictive maintenance, optimizing energy output and reducing operational costs. The successful deployment of AI here demonstrates the importance of data-driven decisions in manufacturing, providing a solid case for Foxconn as it contemplates its own AI strategies.

Another successful instance of AI in manufacturing can be seen at Siemens. The company has employed AI to streamline its supply chain operations. Utilizing AI-driven analytics, Siemens manages to predict demand fluctuations better and allocate resources accordingly, thereby enhancing efficiency. By integrating large language models into their operational frameworks, Siemens can improve their information retrieval processes, allowing employees to access critical data quickly. This approach helps in triggering quicker responses to production needs, offering a roadmap that Foxconn could adapt in its pursuit of AI integration.

Moreover, BMW showcases the power of AI through its smart factories. By employing AI for quality control, the company has been able to identify deviations in manufacturing processes and suggest adjustments in real time, resulting in fewer defects and higher quality products. BMW’s experience highlights the necessity of continuous feedback loops in manufacturing, enabling superior product outcomes. Such insights could be invaluable for Foxconn as it seeks to harness large language models to enhance its production capabilities.

These case studies exemplify various successful strategies for integrating AI into manufacturing, reinforcing the notion that a thoughtful approach, characterized by data analytics and real-time processing, may facilitate a robust and innovative manufacturing environment. Foxconn can draw on these lessons to navigate its own journey in the AI realm effectively.

Conclusion: The Path Forward for Foxconn

In recent years, Foxconn has undertaken a significant shift towards embracing artificial intelligence (AI) technologies, particularly through the integration of large language models. This strategic move marks not only an evolution in its manufacturing processes but also sets a precedent in the industry that could redefine operational standards. As discussed, the incorporation of AI enables enhanced automation, improved efficiency, and streamlined communication, fundamentally transforming the way manufacturing enterprises operate.

One of the critical advantages of Foxconn’s AI push is the reduction of operational costs, which ultimately contributes to a more agile production environment. By leveraging large language models, Foxconn can analyze vast amounts of data, predict trends, and optimize resource allocation with unprecedented precision. This adaptability allows the company to respond swiftly to market changes, ensuring it remains competitive in a rapidly evolving technological landscape.

Furthermore, the deployment of AI technology is set to improve workforce capabilities. By enabling employees to engage with AI systems—which can interpret complex instructions and enhance decision-making processes—Foxconn effectively cultivates a more skilled labor force. This laterally improves job satisfaction and employee retention and aligns talent with technological advancements, reinforcing a culture of innovation throughout the organization.

Looking forward, Foxconn’s commitment to integrating AI within its manufacturing ecosystem serves as a compelling case for other companies in the sector. The necessity of embracing AI technologies has never been clearer; organizations that fail to adapt may risk obsolescence. As Foxconn forges ahead, its experiences and lessons learned will undoubtedly provide invaluable insights for peers and competitors alike, illuminating the path for future advancements in the global manufacturing landscape.